When selecting stylish SPC (Stone Plastic Composite) flooring, we often focus on surface patterns and wear resistance. However, an “invisible” component in the flooring system – the acoustic underlayment – plays an equally crucial role in comfort, noise reduction, and flooring longevity.

The two most common underlayment materials are IXPE and EVA. What distinguishes them? Which better suits your SPC flooring? Let’s explore.

Primary Underlayment Choices: IXPE vs. EVA

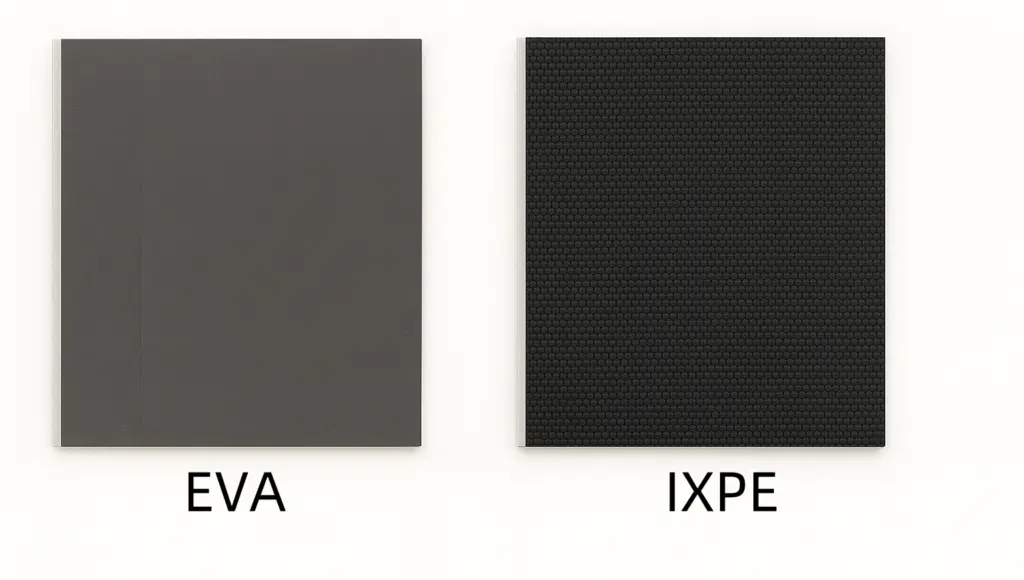

- IXPE (Irradiated Cross-linked Polyethylene)

- Material & Process: Uses low-density polyethylene (LDPE) as the base material, cross-linked and foamed via advanced electron beam irradiation to form a precise closed-cell honeycomb structure. This physical foaming method avoids chemical blowing agents.

- Key Advantages: Eco-friendly, non-toxic, odorless, superior noise insulation, heat insulation, waterproofing, and moisture resistance. Structurally stable with minimal degradation. Check our test report of impact sound insulation for IXPE.

- Applications: Widely used in high-demand scenarios like building insulation, automotive interiors, medical cushioning, premium sports equipment, and SPC flooring underlayments due to its performance and sustainability.

- EVA (Ethylene-Vinyl Acetate)

- Material & Process: A thermoplastic elastomer typically produced through chemical foaming.

- Key Advantages: Offers good flexibility, impact resistance, and lower cost.

- Applications: Widely used in shoe midsoles, packaging materials, yoga mats, and economical SPC flooring underlayments.

Why SPC Flooring Needs IXPE/EVA?

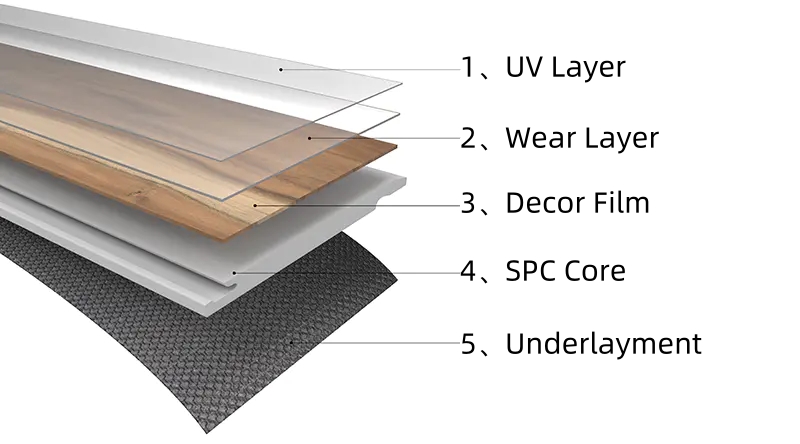

A typical SPC flooring structure (top to bottom) includes: UV layer, wear layer, PVC decorative film, rigid SPC base layer and optional underlayment.

The acoustic underlayment (IXPE or EVA). This layer is critical for:

- Enhanced Comfort: Provides cushioning for softer underfoot feel.

- Noise Reduction: Absorbs footfall and ambient noise, with IXPE’s uniform closed-cell structure offering superior performance.

- Stability & Protection:

- Evenly supports the rigid SPC base layer.

- Compensates for subfloor imperfections.

- Reduces friction between flooring and subfloor, extending the lifespan of the locking system.

- Moisture & Thermal Barrier: Blocks ground moisture and improves insulation.

IXPE vs. EVA Comparison

| Feature | IXPE Underlayment | EVA Underlayment |

|---|---|---|

| Eco-Friendliness | Excellent: Chemical-free, low VOC emissions | Moderate: May emit chemical residues or odors |

| Structure | Uniform closed-cell | Irregular closed-cell structure |

| Density (kg/m³) | 33-90 (lighter) | ~100+ (heavier) |

| Comfort | Superior (soft yet resilient) | Good (elastic but firmer) |

| Production Cost | Higher (complex process/equipment) | Lower (simpler process) |

Note: Higher density correlates with better performance. Comparison based on typical SPC underlayment specs.

How to Choose IXPE and EVA?

Choose EVA When:

- Budget-Conscious: Ideal for tight budgets (20%-30% cheaper than IXPE).

- Short-Term Use: Rentals/temporary installations where long-term durability isn’t critical.

- No Underfloor Heating: Suitable for stable-temperature environments without radiant heat.

Choose IXPE When:

- Health Priority: Homes with children/elderly/allergy-prone individuals, or hospitals/schools requiring high air quality.

- Premium Experience: Seeking superior comfort and noise reduction.

- Long-Term Investment: Prioritizing system durability and stability.

- Radiant Heating: Heat-resistant IXPE ensures safe performance with underfloor heating.

Conclusion: Choices with Needs and Value

IXPE excels in eco-friendliness, durability, and acoustics for premium applications, while EVA meets basic needs cost-effectively. Choose based on budget, environmental factors (e.g., heating), and health priorities. As sustainability standards rise, IXPE adoption in SPC flooring is poised to grow.