In the world of home decoration trends, flooring has long moved beyond the single attribute of “durability.” As aesthetic preferences shift from luxurious gloss to understated texture has emerged: ultra-matt flooring.

Today, ultra-matt technology is increasingly being applied to SPC flooring and LVT flooring. So, what exactly is it? And what groundbreaking technology does it conceal?

The Secret of Gloss

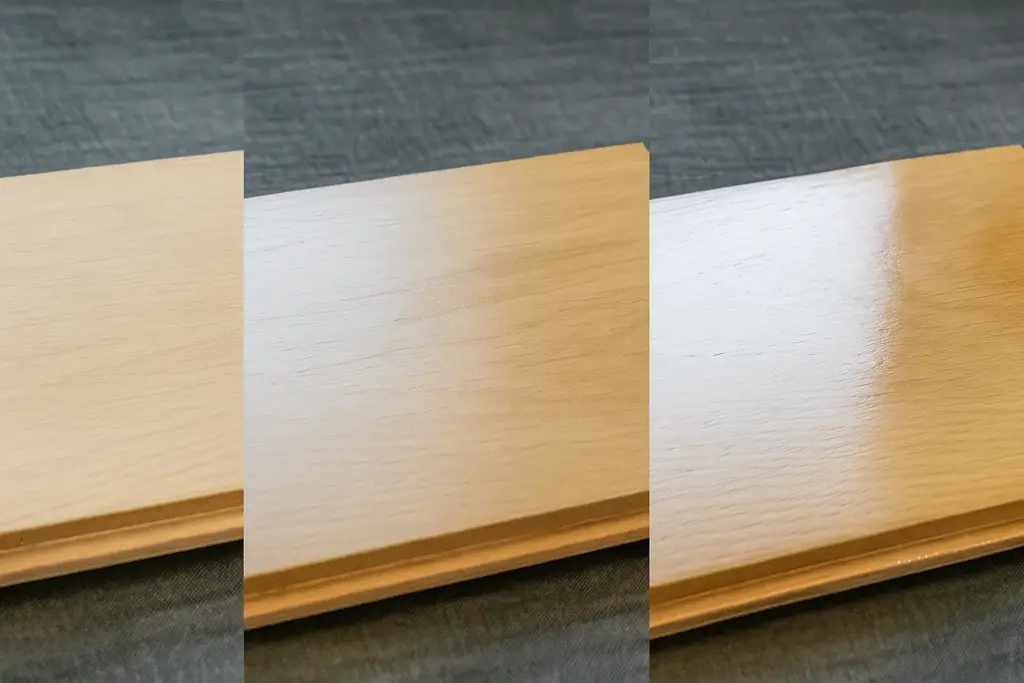

In the industry, we use a Gloss Meter to quantify the reflective intensity of a surface in units of GU (Gloss Unit). This provides us with a clear benchmark for judgment of gloss:

- Traditional Matt/Low-Gloss SPC Flooring: Typically has a gloss level between 3-7 GU, still existing some light reflection.

- Ultra-Matt SPC Flooring: Thanks to new technology, its gloss level can be controlled within 0-2 GU, producing almost no specular reflection and presenting an ultimate, pure matt surface.

Ultra-matt Tech Unveiled

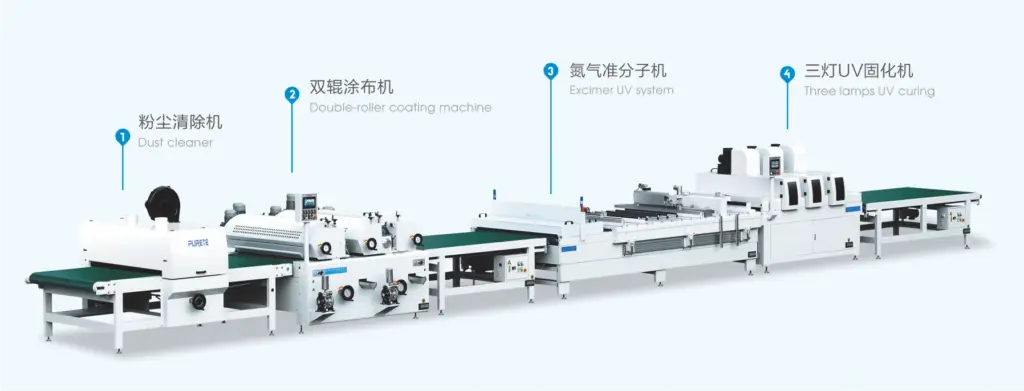

Achieving such an extreme matt effect doesn’t rely on traditional methods. At its core is a cutting-edge physical technology known as 172 nm Excimer curing.

Let’s use a simple analogy to understand:

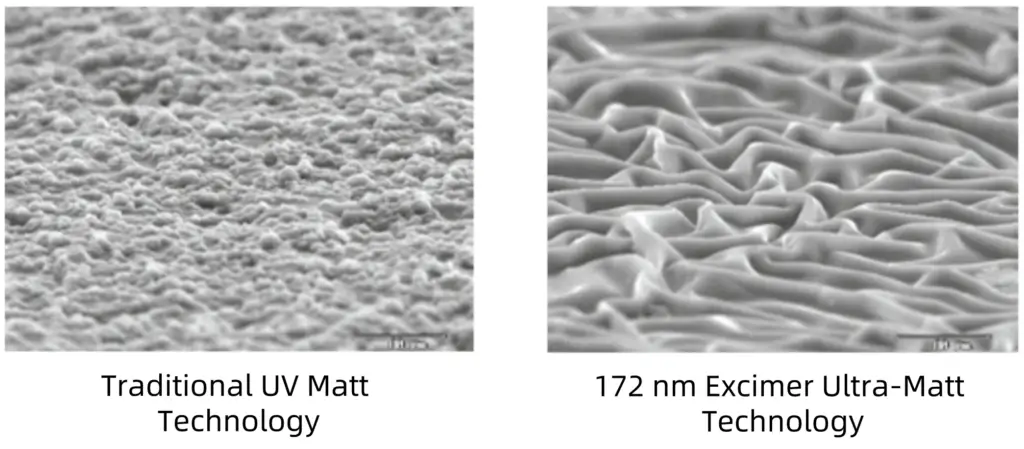

Traditional Matt Finishing: This is like mixing extremely fine “sand” (matting agents like silica) into a clear UV lacquer. The matt effect is achieved as these particles diffusely reflect light. However, the downside is that it sacrifices the coating’s transparency, making the flooring pattern appear slightly “hazy.”

172 nm Excimer Technology: This method adds nothing to the lacquer. Instead, it uses a specific wavelength of light—172 nm excimer light—to instantly irradiate the surface of the freshly applied, wet UV lacquer. This high-energy light acts like a magical breeze rippling the surface of a lake, creating a microscopic, uniform, wrinkled texture on the very top layer of the lacquer (only a few hundred nanometers thick), and instantly “freezes” (cures) it.

This physical texture perfectly scatters light in all directions, achieving the ultimate matt effect. Afterward, conventional UV lamps are used to completely cure the entire lacquer layer, ensuring its hardness and durability.

The Ultimate Showdown: Ultra-Matt vs. Traditional UV

To illustrate the differences more intuitively, let’s compare them in a table:

| Feature | 172 nm Excimer Ultra-Matt | Traditional UV Matt |

|---|---|---|

| Principle | Physical Matting: Polymerization shrinkage on the coating surface creates a micro-wrinkled structure that scatters light. | Chemical Matting: Matting agent particles, such as silica (SiO₂), are added to the coating. |

| Process | Relatively complex: Roller coating -> Excimer lamp irradiation -> Conventional UV lamp curing. | Relatively simple: Roller coating -> Conventional UV lamp curing. |

| Gloss Level | Low and uniform (0-2 GU). | Lower (typically >3 GU), less uniformity. |

| Production Cost | Higher. Currently, the cost per square meter is about $1 higher than the traditional process. | Lower, with mature technology. |

Why Do We Need Ultra-Matt SPC Flooring?

Choosing ultra-matt SPC flooring isn’t just about chasing a trendy term; it’s about aspiring to a whole new living experience:

- Aesthetically Driven: It perfectly caters to the demand of mainstream interior design styles like modern minimalism, wabi-sabi, and “creamy” style for soft, serene, and natural lighting.

- Enhanced Experience: The unique “skin-touch” surface offers a texture close to that of real wood.

- Function Meets Form: With its excellent scratch resistance, stain resistance, and anti-fingerprint properties, ultra-matt SPC flooring truly resolves the conflict between stunning aesthetics and everyday practicality.

Ultra-matt SPC flooring, based on 172 nm Excimer technology, represents a comprehensive innovation, inside and out. Offering a superior solution for modern living spaces. Here is our SPC Product for your review: