In today’s pursuit of personalized and high-quality home decoration, flooring materials have long transcended their basic function to become a key element of interior aesthetics. Beyond traditional SPC planks, a “new darling” with a greater sense of art and design—SPC Parquet, has begun to capture people’s attention.

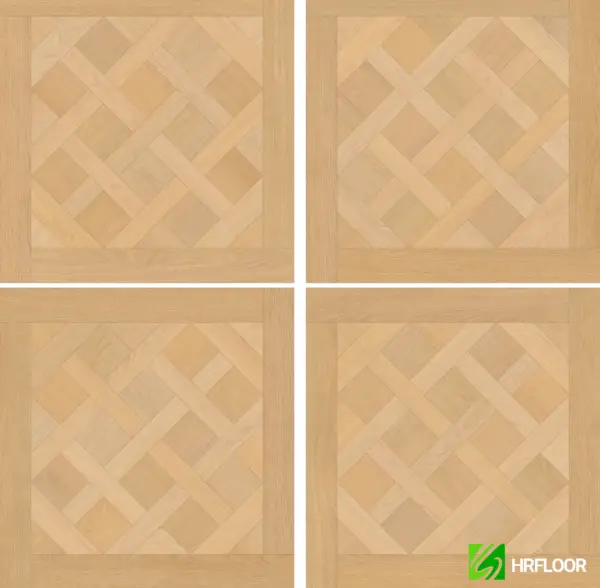

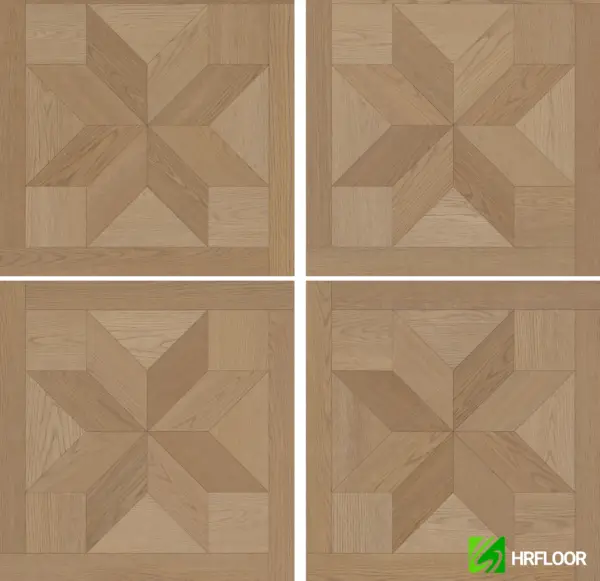

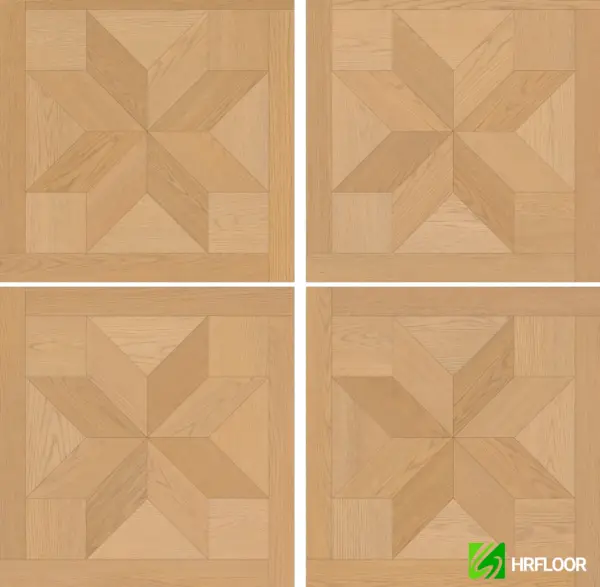

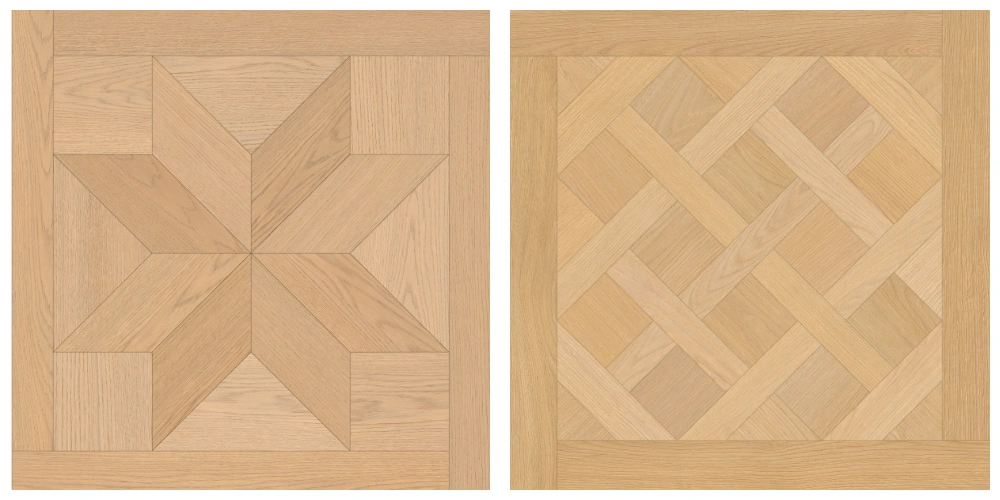

Parquet, derived from French, means “inlaid work,” a style of flooring that involves assembling small pieces of wood into geometric or decorative patterns (such as Herringbone, Chevron, Versailles palace style, etc.).

SPC (Stone Plastic Composite) is a stone-plastic composite material. When the high-tech,o-friendly material SPC meets the classic art form of Parquet, SPC Parquet flooring is born. However, while solid wood and laminate parquet flooring are commonplace, high-end SPC Parquet remains relatively rare in the market. This scarcity conceals profound technical barriers and cost considerations.

Why is SPC Parquet So “Rare”?

The scarcity of SPC Parquet is no accident; it is rooted in revolutionary changes in the manufacturing process and the resulting high costs.

1. Manufacturing Process From “Extrusion Embossing” to “Multi-Layer Pressing”

The core production process for traditional SPC flooring, the common plank format, is “extrusion + embossing”. After the core material is formed in an extruder, it passes through a four-roll calender where the PVC color film, wear layer, and SPC core are put together in a single pass by heat and pressure.

While simultaneously embossing a wood or stone texture. The drawback of this process is that the extrusion inevitably stretches the surface PVC film, causing patterns—especially the precisely aligned patterns required for parquet—to deform and misalign. This makes it impossible to achieve “Embossed In Register” (EIR) texturing, where the embossed texture perfectly aligns with the visual pattern of the color film.

In contrast, SPC Parquet, especially large square formats like 600x600mm, demands extreme fineness in texture and precision in alignment. To achieve a texture and appearance comparable to real wood, it must abandon the traditional extrusion process and adopt a “multi-layer hot press” manufacturing process similar to that of LVT flooring. This process involves layering all functional layers (core material, color film, wear layer, etc.) and then feeding them into a large hot press for an extended period under precisely controlled temperature and immense pressure. This method prevents the color film from stretching, allowing for perfect Embossed In Register (EIR) texturing. The result is an incredibly accurate and realistic.

This change in production procedure directly leads to an increase in cost.

2. The Cost of EIR Molds

The core reason for the high cost of SPC Parquet also lies in the difference in molds. Traditional SPC with EIR only requires developing one set (a single) embossing roller that matches the color film pattern. But for SPC Parquet made with a hot press, ensuring production efficiency requires the simultaneous development of at least 10-20 individual EIR steel press plates. This enormous upfront investment in molds is one of the main deterrents for traditional SPC flooring manufacturers.

The Advantages of SPC Parquet

Despite its high manufacturing cost, SPC Parquet holds irreplaceable value in the high-end market thanks to its unique advantages. The following table clearly illustrates its positioning.

| Compared To | SPC Parquet | SPC Plank | Hardwood Parquet | Laminate Flooring |

|---|---|---|---|---|

| Size & Spec | Square, e.g., 600x600mm, 1215x405mm. Strong design sense, high visual impact. | Long plank, e.g., 1220x180mm, 1524x228mm. More conventional. | Mostly long planks; parquet patterns require on-site installation. | Rich variety of sizes and specifications. |

| Aesthetic Value | Patterns inspired by classic Parquet art like herringbone, Versailles, etc. Inherently luxurious and artistic, a focal point of interior design. | Imitates conventional wood or stone grain. | Natural grain, warm texture. | Printed texture, can imitate various patterns. |

| Waterproof Performance | Stone-plastic core, completely non-absorbent, 100% waterproof. Can be used in any damp environment like kitchens, bathrooms, and basements. | Same as SPC Parquet. | Not water-resistant; prone to swelling, warping, and cracking when exposed to water. | Has some moisture resistance, but core is HDF, which will swell and deform severely with prolonged water exposure. |

| Environmental Performance | No adhesives are used in the production process, achieving “zero formaldehyde” emissions. | Same as SPC Parquet. | Natural wood is inherently eco-friendly. However, surface finishes may contain VOCs. | Adhesives are used in the core production, containing formaldehyde. |

As an emerging product in the flooring industry, SPC Parquet is not just a change in specification from traditional SPC flooring; it is a significant innovation in production technology and design philosophy. From extrusion to hot pressing, and on to complex EIR technology, these advancements endow SPC Parquet with an unparalleled delicate texture and artistic beauty.