When laying a floor, we often focus on the color and material of the flooring itself, overlooking the inconspicuous “unsung hero” beneath our feet—the underlayment. Underlayment not only improves the underfoot feel and extends the life of the flooring but is also key to correcting uneven subfloors and providing moisture resistance and acoustic insulation.

Among the many underlayment materials, XPS underlayment is becoming the choice of more and more professional flooring manufacturers due to its outstanding overall performance.

So, having previously discussed the differences between IXPE and EVA, what exactly is XPS underlayment? And what are the core differences between it and the common IXPE and EVA underlayments?

XPS: Introduction and Advantages

XPS underlayment, short for Extruded Polystyrene underlayment, is a high-strength, closed-cell foam board primarily installed between the flooring and the concrete subfloor.

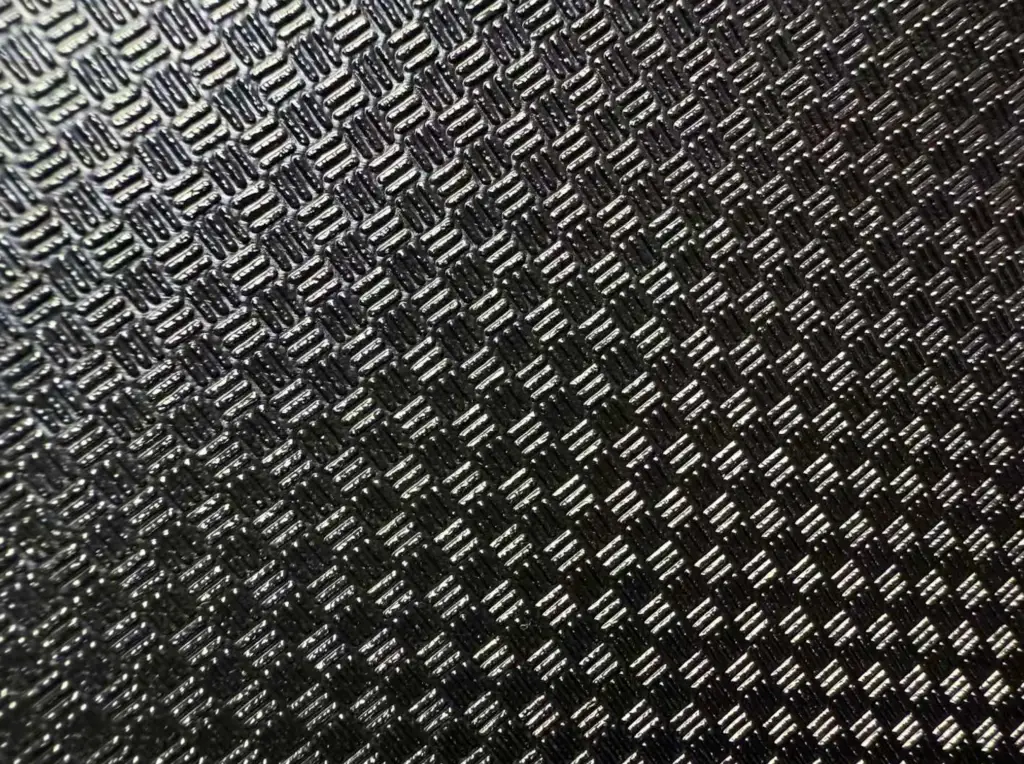

Its core advantages stem from its unique physical structure: a continuous and uniform closed-cell honeycomb structure. You can imagine it as countless tightly connected, sealed air cells forming its main body. This structure endows XPS underlayment with a series of outstanding properties:

- High Compressive Strength and Leveling Ability: The dense closed-cell structure allows it to withstand significant pressure, effectively preventing the floor from developing indentations or gaps under long-term heavy loads. At the same time, it can adapt to minor height differences in the subfloor, achieving “self-leveling” by compressing underfoot, ensuring a flatter flooring installation.

- Excellent Moisture Resistance and Acoustic Insulation: The fully enclosed cell structure acts as a barrier, effectively blocking moisture from the subfloor and preventing the flooring from getting damp and moldy.

- Thermal Insulation and Energy Saving: In homes with underfloor heating, using XPS underlayment can significantly reduce heat loss and lower energy consumption.

- Stable and Durable: The XPS material itself is chemically stable, resistant to corrosion and pests, ensuring an exceptionally long service life.

XPS vs. IXPE vs. EVA

To more clearly understand the positioning of XPS, we will compare it with two other mainstream underlayment materials on the market—IXPE and EVA. The following charts and analysis will cover three dimensions: eco-friendliness, physical properties, and cost.

1. Eco-Friendliness Comparison

When choosing materials that will be in close contact with the home environment, eco-friendliness is a primary consideration.

| Material | Eco-Friendly Features | Potential Risks |

|---|---|---|

| XPS | Modern processes often use CO₂ foaming agents, which are fluorine-free and recyclable | Traditional chlorine-containing foaming agents (HCFCs) have been gradually phased out |

| IXPE | Physical foaming, no chemical residue, recyclable | Virtually no pollution, recognized as an eco-friendly material |

| EVA | Some low-end products may contain formamide; recycled materials often have an odor | Poor-quality products carry the risk of releasing formaldehyde |

IXPE’s eco-friendliness is the most outstanding. XPS produced with modern processes is also very eco-friendly, especially products using carbon dioxide foaming technology. In contrast, EVA underlayment may have an odor during use.

2. Physical Properties Comparison

Physical properties directly determine the functional performance and durability of the underlayment and are mainly related to density. Currently, the flooring industry mainly uses 10x and 15x IXPE, and medium-to-high density EVA. In flooring applications, the density of XPS is comparable to 10x IXPE.

| Parameter (same thickness) | XPS | 15times IXPE | 10times IXPE | Medium-density EVA | High-density EVA |

|---|---|---|---|---|---|

| Density | 90-110 kg/m³ | 60-75 kg/m³ | 90-110 kg/m³ | 60-80 kg/m³ | 110-120 kg/m³ |

3. Cost and Application Scenarios

| Parameter (same thickness) | XPS | IXPE | EVA |

|---|---|---|---|

| Price | Medium | High | Low |

Underlayment Selection for SPC Flooring

In recent years, SPC (Stone Plastic Composite) flooring has gained popularity due to its high strength and water resistance. And XPS underlayment, with its advantages in performance and cost, is gradually becoming a common base layer material for SPC flooring. Overall, there is no single best material, only the most suitable one for a given application.

- Typical Residential Applications: If you’re looking for eco-friendliness, quietness, and good value, IXPE underlayment is undoubtedly the ideal choice.

- Commercial Spaces or Humid Environments: For shops, offices, basements, or homes with underfloor heating systems, the ultra-high compressive strength, moisture resistance, and insulation benefits of XPS underlayment are irreplaceable.

- For Budget-Driven Projects: High-density EVA can serve as a low-cost solution for short-term or temporary use.